The plastics industry is considered one of the most important industries that have gained significant importance in the recent period, as plastics have become involved in many other industries and thus become an essential element in our daily lives, there is no product without the plastic being one of its components or one of the components involved in its manufacture and producing starting from the plastic bags that involved in the packaging industries, going through the plastic packaging for the products (dairy- juices- medications- cleaning products- ....) as well as the electrical appliance industry, automotive industry, and many other products that need plastic materials to produce them, and because of the increasing demand for the plastic products, the need to set up many plastic factories has increased, as there are many different plastic products such as (plastic bags- packaging- plastic chairs and tables- plastic household appliances.....) and other products, and necessarily there are thousands of factories specializing in the production of one or more plastic products, there are many plastic factories that produce thousands or even millions of the products are produced daily, the plastic manufacturing process is mainly due to converting plastic raw material (polyethylene) into finished products, for the manufacturing to be completed must go through more than one stage starting from melting raw material process (polyethylene- polyvinyl chloride), then the extrusion process and converting the raw material into a liquid material that is withdrawn through a film machine and then the forming process, and this stage is done in more than one way, according to the product to be produced, the production process may be done through (plastic blowing- plastic molding- plastic injection...), then the plastic will be subjected to the cooling process to get the finished product and due to the high volume manufacturing of plastic products, the factory may produce thousands of plastic products per day that need to control the production process and costs because of what these products represent of (raw materials- direct costs- indirect costs), and therefore the factory needs an accounting software capable of managing the production process, calculating the costs and managing the human resources, as well as providing the company’s departments with the reports and information they need to help in the management, control, and decision-making, and we will discuss the role of one of the best plastic manufacturing management software, which is AccFlex ERP Software.

AccFlex ERP System

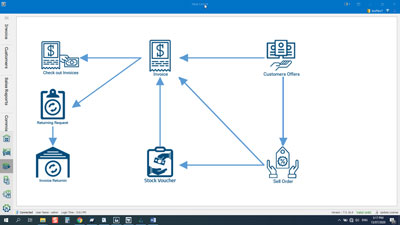

AccFlex is an integrated ERP system for managing any company, as the system contains a set of integrated modules that provide each other with information and reports, and any impact on any module of AccFlex ERP System affects the other module, for example, when creating an item in Inventory Management Software, Production Planning Software is affected as well as General Ledger Software and so on, we will discuss the role of AccFlex ERP Production Planning Software in managing the plastics manufacturing industry.

AccFlex Production Planning Software for Plastics Industry

AccFlex Production Planning Software is characterized by it provides a simulation model for the production process management inside the plastic factory, so the production cycle in the software begins with

1- Creating and coding the raw materials (Polyethylene- Polyvinyl chloride) in AccFlex ERP Inventory Management Software by entering the Item Name, Item Code, Unit of Measurement, Item price, the warehouse in which the item is available, and the alternative items in case no balance of the item is available and selecting the item as a raw material in the software.

2-The finished product items are created (plastic packaging- bags- bottles- dishes ....), the finished product components are determined of the raw materials used in the manufacture by precise proportions to produce one unit of the item, for example, the plastic packaging may need 100 mm to be produced (50 mg Polyethylene- 20 mg Poly Vinyl Chloride- 30 mg Recycled Plastic … and so on) the price of the item, the warehouse to which the item is added, unit of measurement, and other finished product data are selected.

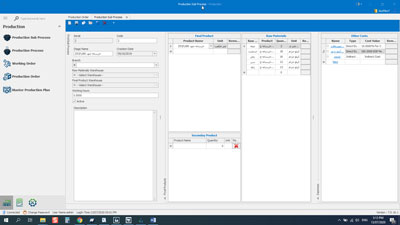

3- Through AccFlex Production Planning Software, the production stages of the product are planned, through the (Sub-production Process) screen, which creates more than one production process and to determine what the production process needs (sub-final) of (raw materials- number of operating hours- direct costs), as well as, determining the spoilage ratio per sub-production process, such as creating the plastic blow molding process, as a sub-production process when producing the 100 mm plastic packaging, as the plastic packaging production passes through more than one stage, and more than one sub-production process is created according to the actual production processes.

4- Through the Production Process screen in AccFlex Production Planning Software, the actual manufacturing process is planned by determining the percentage of completion of each sub-production process in the production of the finished product, such as determining the heating of plastic process representing 10% of the production of the finished product, as well as the plastic molding process as 40% of the production process, and so on, and the software links the production processes to each other based on their arrangement to the production process, leading to the 100% completion rate of the product production process.

5- Through the Work Order screen in AccFlex Production Planning Software, the desired quantity for production is entered of a specific product for a customer, and the software automatically calculates the required quantity of raw materials needed to produce this quantity of the finished product (e.g. plastic bags).

6- When starting the actual production process, the user enters the Production Order screen in AccFlex Production Planning Software and selects the quantity that will be produced, and when selecting the finished product to be produced (e.g. plastic bottles), the software displays the quantities of the finished product of the raw materials, as well as the direct costs, actual production hours, and the machines used in the production process such as (cutting machine- press- welding machine- scale- crushing machine- etc.) the user can adjust the quantities according to the actual production process, the software is characterized by simplicity and ease in the production process, once you click the Raw Material Withdrawal and Adding Finished Product Quantities, the production process is completed.

7- AccFlex Production Planning Software provides you the ability to allocate the indirect costs to the finished product costs, and more indirect costs can be added to the finished product such as (factory rent- electricity bills- utility bills- security guards costs...) and through the Indirect Costs Allocation screen, the period and cost value are selected and the software automatically allocates the indirect costs to the products, in addition to linking the direct costs to the finished product directly, giving more accurate costs for the product.

8- AccFlex Production Planning Software also provides for the plastic factories with the most accurate reports that help them in the product cost management and controlling the quantities of raw materials and the finished product, as well as monitoring the elements of costing and budgets, which will always help the department moving in the right direction, whether in the manufacturing processes or cost management, it also provides the production department and other company departments with the reports they need.

AccFlex ERP General Ledger Software for Plastics Industry

If you are looking for suitable general ledger software for the plastics industry, your choice of AccFlex ERP General Ledger Software is the right choice, as the software has the efficiency and accuracy of the GL accounts management, and perhaps the most important characteristics are the following:

1- Flexibility in dividing the accounting periods, a fiscal year can be divided into one accounting period, two accounting periods, four accounting periods (a period every 3 months), or twelve-month accounting period (monthly accounting periods), helping in the control and ease of closing each period separately.

2- The ability to posting the balance of a specific period, depreciation of its assets, and posting its revenues and expenses automatically through the software without the need to prepare closing entries.

3- Tax periods control, can be entered the tax payment data for withholding and collection taxes (a period every 3 months) Form no (41 Withholding and Collection) and closing tax period through the software.

4-The software provides a complete system of tax transactions management such as linking suppliers and customers to tax accounts and creating and automatically calculating VAT Notifications through the software (Value Added Tax - Form-10).

5-AccFlex ERP General Ledger Software has a more flexible chart of accounts than any other software; the chart of accounts can create an infinite number of accounts as soon as possible and allows you to correct errors as they occur when creating an account by mistake, and we want to cancel it, through the “Transfer-Transactions” button easily the transactions made on the wrong account can be transferred to the correct account with the freedom to save the account or delete to save more time and effort in entering the transactions, as well as the ability to change the properties of the child accounts of the chart of accounts and transfer them to the correct side.

6- The software allows you to add Opening Balances to general ledger accounts from an Excel file, in a split second; you can add an infinite number of balances.

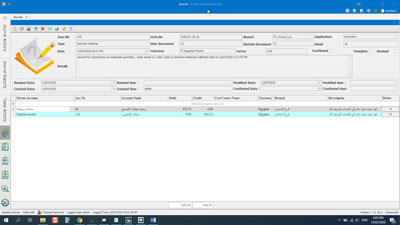

7- The Create Journal Entry screen of AccFlex ERP General Ledger Software has many advantages, allowing you to add journal entries directly from an Excel file, adding an infinite number of journal entries, add and save attachments to the journal entries, and have more than one reference number of the journal entry that the software creates automatically through which to search, you can create a journal entry template and use it more than once.

8- The Reversing Journal Entry screen once you select it and click Save, and the presence of a screen to review and approve journal entries through which the journal entries can be displayed by all their sides and details and you can display by a particular type of journal entries or all journal entries.

9- Flexibility in creating an infinite number of custom screens in the account management such as (Treasury Screen, Bank Screen, Receipts Screen, Payments Screens, etc.).

10- The ability to create an infinite number of branches and cost centers and assigning them to the accounts.

11- Dealing with multiple currencies and multiple exchange rates in the software with the possibility of selecting the accounts that accept changing the currency.

12-The software provides a unique set of reports that provide the finance department and other departments with the financial reports, the software provides the General Ledger report, Subsidiary Ledger report, and Subsidiary Ledger Report for Cost Centers, as well as the Financial Statements (Balance Sheet- Financial Position- Budget- Income Statement- Trial Balance- American General Journal), can be displayed in more than one format, and the Condensed Income Statement can be displayed or creating an Income Statement/Financial Position template to be displayed.

AccFlex ERP Fixed Asset Management Software for Plastics Industry

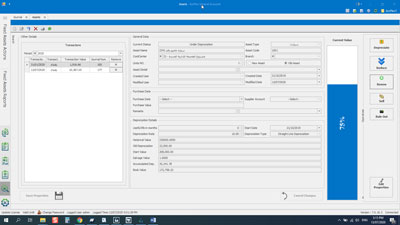

Fixed assets represent a large part of the capital of the companies, which are the production machinery and equipment used by the plastic factory in producing the finished product such as (Hydraulic Scissor, Plastic Blowing Machine, Tempering Furnace, Scale & Balance, Press, Distribution Vehicles, Plastic Injection Molding Machine, ...) their production status must be monitored and calculating their depreciation and linked to cost centers, companies often need to invest in a software that does this role, but the advantage of AccFlex ERP General Ledger Software is that it contains a Fixed Asset Management Module as an integral part of General Ledger Software and has many advantages, including

1- Creating an infinite number of fixed assets and add them through an Excel file.

2- The ability to add the company's assets, determining their value, the date they were added to the company, cost center, and determine the depreciation method.

3- The ability to create various transactions on the assets (depreciation- disposal- scrapping- write-off- selling- renewal-...) the software automatically creates journal entries and affects the chart of accounts and the ability to transfer the asset from one location to another, and assigning it to cost center, as well as selecting the employee who has custody of assets.

4- AccFlex ERP Fixed Asset Management Software provides a set of unique reports on fixed assets that enable the department to track, control, calculating depreciation, status monitor of the fixed assets, and also to create various transactions on the fixed assets (appreciation- disposal- selling- scrapping...).

AccFlex ERP Inventory Management Software for Plastics Industry

Many plastic factories face difficult issues managing their warehouses, as the plastic companies produce thousands of diversified plastic products daily, making it difficult to inventory control these products and limit the goods receipt and goods issue transactions from the warehouses, which may incur these factories a lot of losses due to what they lose of products due to the difficulty of the warehouse management processes, but through AccFlex ERP Inventory Management Software, the plastic factory can the warehouse management accurately and easily, the software is based on the automation in the input, and products can be added directly from the production line to the warehouse through the barcode, once the product barcode is added, the software immediately affects the inventory item balance, as well as the inventory account in the chart of accounts as well as the production costs, as well as once the product is issued, the inventory item balance, sales, and all parties related to the transaction, are affected because the software automatically creates the journal entries.

AccFlex ERP Inventory Management Software enables creating an infinite number of plastic products and add more than 14 codes for each item with the ability to search for the item with any code, as well as the ability to add the item to more than one warehouse and determine the price of the item within each warehouse and can determine more than one price of a single item (selling price- retail price- wholesale price ...) in addition to assigning the unit of measure to the item, it is possible to assign more than one unit of measure to the item and convert between them, as well as the ability to link the item to an alternative item group that appears automatically when the stock-out or linking the item to a group of components.

AccFlex ERP Inventory Management Software enables entering item opening balances, it is possible to add the opening balances for an item group through an Excel file in a split second, as the software supports the feature of importing from an Excel, and the reorder point can be set for each item (The number of units that should be not less than the inventory stock so that the workflow cannot be interrupted) once the level of inventory reaches the reorder point, the software will display a warning message.

Likewise, through AccFlex ERP Inventory Management Software, the plastic factory can manage the stocktaking process and making inventory adjustments easily, through the software, enables you to export the book balance of items and compare the actual balance to the book balance, the items balances were then entered through an Excel file, as the software supports importing from Excel to save more time and effort in the input processes and helps to enter an infinite number of items in a split second, as the software supports importing from Excel to save more time and effort in the input processes and helps to enter an infinite number of items in a split second, as well as once the software gets the actual balance, it performs the inventory adjustments automatically and determines the decrease or increase in the items and the software creates the adjusting entries automatically, the software also provides you the ability to transfer between the warehouses and make the adjustments receipt or issue items.

Through AccFlex ERP Inventory Management Software, can get a unique set of reports on the item balances, inventory balance, and item balance in each warehouse, as well as displaying the Stocktaking report, Inactive Items report, Fast Moving Item report, Reorder Point report, and other unique reports on the items and warehouses.

AccFlex ERP Inventory Management Software for Sales and Purchasing Management for Plastics Industry

Sales and purchasing are the basis of the production process and business process, as any commercial activity produces income and for this profit to be achieved, there must be customers, but with the diversity and multiplicity of customers and suppliers and the increase in the sales and purchasing transactions, it is difficult for the plastic factory to manage the sales and purchasing, and AccFlex ERP Inventory Management Software provides a great and excellent model for managing sales and purchases.

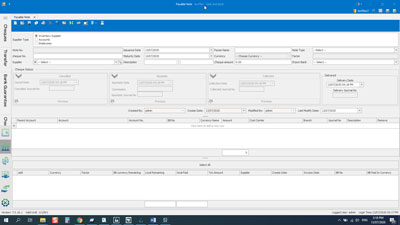

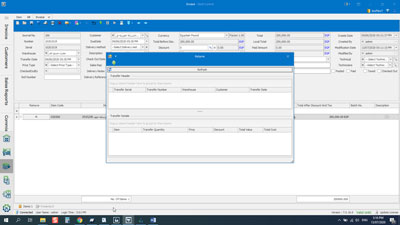

1- Purchasing & Accounts Payable in AccFlex ERP Software

AccFlex ERP Inventory Management Software provides a typical procurement cycle starting from (determination of requirements- then determine the source of supply- followed by the vendor selection- then comparing quotations- after determining quotations, the lowest price and the best quality, the purchase orders are created- then a delivery note can be issued to vendors- then the invoice verification) and the payment process management, and the plastic factory can adhere to this typical cycle or complete the purchase process at any stage of it, the software has the flexibility to help you manage your business however you want, the purchase invoice in AccFlex ERP Inventory Management Software contains a set of features, the items can be added to the purchase invoice in more than one way or creating the purchase invoice with reference to the purchase order or the quotation, can also be linked to a group of discounts at the invoice level or the item level and linked to a tax group directly to make it easier to calculate the tax invoice, also can re-open an invoice and creating a return for some of its items, and the software automatically affects all accounts related to the invoice (inventory- accounts payable- taxes- product costs- .......).

AccFlex ERP Inventory Management Software, an infinite number of suppliers can be created, assigning each supplier to a group of items that he supplies, as well as determining whether this supplier is cash or credit, setting the credit limit and the debt period, linking the supplier to the prices of the items he supplies, and assigning the supplier to his quotations, and setting the opening balance and current balance, the software also has screens for debugging, if more than one code is created for a single supplier, they can be combined into one code even if the transactions were made on each of them through the " Merge Suppliers" button, which transfers the transactions of the wrong supplier to the correct supplier in a split second without the need to cancel the transactions and re-enter them again.

The software also provides a unique set of reports covering all information about the purchases, purchased items, and their quantities as well as the accounts payable balance, debt period, and other reports that provide the company’s departments with the information they need and help the senior management in making decisions.

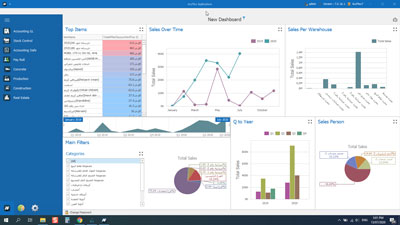

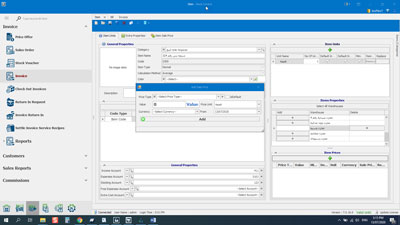

2- Sales & Accounts Receivable in AccFlex ERP Software

Likewise, AccFlex ERP Inventory Management Software provides a typical sales cycle, begin by creating the quotations to customers until converting the quotation to a sales order, then the delivery note voucher is issued from the warehouse, then issuing invoices and a sales invoice can be created directly without restricting with the sales cycle or creating a sales invoice with reference to the quotation or the sales order, the software has a great degree of flexibility, and as with the purchase invoice, the sales invoice also has a set of advantages that make creating the sales invoice easier, and it is also possible through the software to create a return request of the items from the customer and create a return transaction (sales returns).

As for customers, through the software can add an infinite number of customers, selecting whether this customer is cash or a credit customer, setting the credit limit allowed for the customer and the maturity period, as well as add the customer opening balance and know the customer status and his current balance and whether exceeds the credit balance or not and all the cash transactions that were made on his account, the customer credit data can be added such as the Customer Bank Name and Account Number as well as assigning each customer to a group of offers and can be copied to another customer, in addition to the ability to close the customer invoices and matched with their payments.

The software has a unique set of reports covering all the needs of the plastics factory on the sales process, whether the sales invoices or sales quantity of each item, as well as displaying the quotations, accounts receivable balances, the status of each customer, and reconciling the accounts receivable through the software, as well as reports on Sales Returns, their status, and many reports that provide the company departments with the information they need.

AccFlex ERP Treasury & Banking Software for Plastics Industry

Cash transactions are the basis of the corporate business because the cash is the primarily driven the production transaction, the plastic factory can only purchase the raw materials by getting its dues from the customers and also cannot purchase the necessary raw materials except by paying the dues of the suppliers as well as the employee salaries and other costs and the treasury and banking transaction is characterized by the intensity of the volume of transactions, and therefore it was necessary to tighten controls on all transactions of the treasury and banks, through AccFlex ERP Treasury & Banking Software, the plastic factory can do this, as the software is characterized by a set of advantages that distinguish it from any software for managing the treasury and banks, including

1- Once you login AccFlex ERP Treasury & Banking Software will show you all notes payable and notes receivable, helping to manage cash flow over the next period.

2- A sub-module related to the treasury management has the Receipts screen and the Payments screen through which linking payment/ treasury income to customer and supplier invoices, selecting the AP/outstanding invoice and the software can select the type of supplier/ customer to be paid for him (warehouses suppliers- accounts….) and once the supplier has selected, all AP invoices are shown as well as the customer, making it impossible to repeat the payment.

3- A sub-module related to the bank management has screens for managing the notes receivable and another for managing the notes payable through which the payment/collection can be linked to customers and suppliers.

4- The ability to design and print the check through the software as well as entering the check serial number and the software automatically adds the check number at the time of payment.

5- The ability to make the bank transfers to suppliers and customers through the software.

6- The ability to make transfers between banks and treasuries or between banks and treasuries easily.

7- The ability to manage letters of guarantee and adjust letter of guarantee status (increase the letter of guarantee value- decrease the letter of guarantee value- liquidate a letter of guarantee- cancel a letter of guarantee).

8- The software automatically creates all journal entries and affects the chart of accounts by all transactions from the Treasury & Banking screens.

9- AccFlex ERP Treasury & Banking Software provides a unique set of reports that provide the finance department in the plastic factory and other departments with financial information about the cash flow and treasury (receipts-payments) and the bank (notes receivable- notes payable- bank transfers- internal transfers- letter of guarantee management...) as well as about the accounts receivable, accounts payable, petty cash, and others making the treasury and bank management of plastic manufacturing industry easier and more accurate.